Written in collaboration with our Supply Chain Advisor, Amy McClenathan.

Cutting costs has always been the name of the game in the oil and gas industry. While just yelling at your vendors works occasionally, the real ROI comes from efficiency gains like trimming waste, eliminating unnecessary work, and rooting out fraud. Again and again, these successes come through technological advances and process improvement.

And for the last several years, there has been a renewed push to find efficiencies through the utilization of software and data analytics. Most of these efforts have been focused on the operations teams of E&Ps – frac designs, artificial lift, and A&D efforts.

But there’s a huge opportunity in Supply Chain, too – we’ve seen and heard of great Supply Chain teams achieving savings like 3.5% of total spend or 10% per service category. This might come as a surprise to some, so let’s dive in and talk about how the Supply Chain team can become the next frontier of efficiency.

The Next Frontier

Supply chain and COVID-related issues have gotten a lot of press lately, but what exactly do we mean when we talk about Supply Chain?

Across many industries, the Supply Chain encompasses many functions including:

- Procurement

- Inventory Management

- Materials Management

- Strategic Planning

- Distribution

- Logistics

In the context of upstream oil and gas, and more specifically E&P companies, the Supply Chain team is traditionally seen as the procurement arm of the company – where we can get the goods and services we need for the best cost. And while this is an important function of the group, it can do so much more.

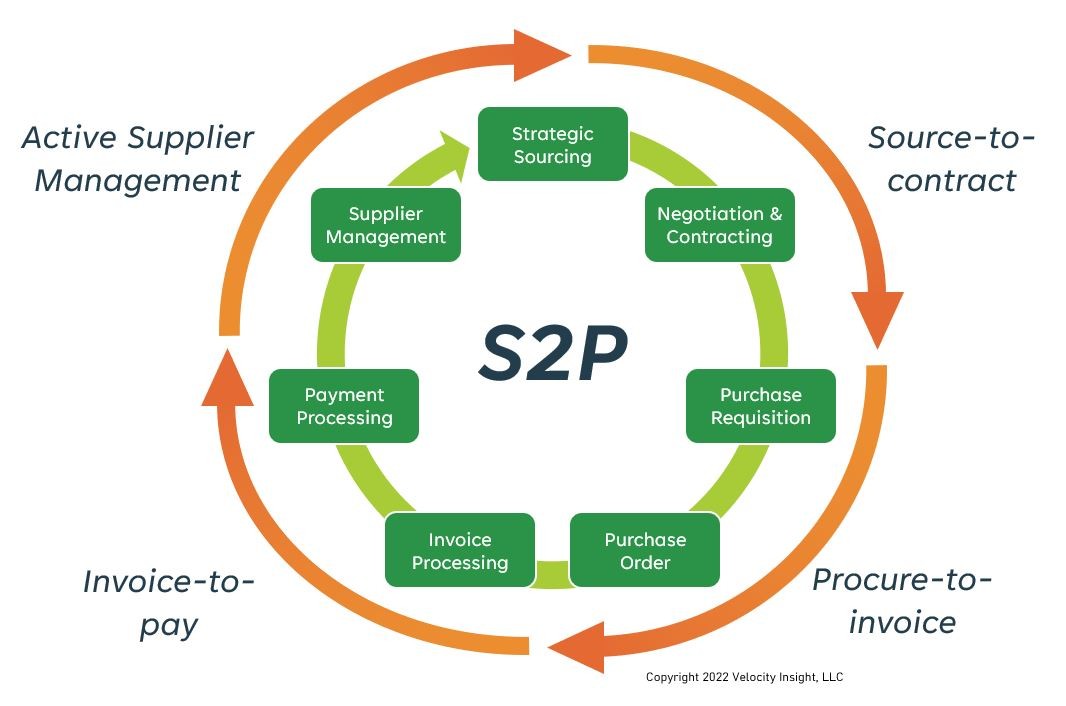

The Supply Chain team is the keeper of what we call the Source-to-Pay process (S2P). The end-to-end process may take on different steps depending on how your company is set up, but the process starts with the sourcing of goods or services through either strategic sourcing or purchase order requisitions and ends with payment processing. No matter the maturity of your Supply Chain team, the invoice-to-pay process is present. It’s how your suppliers bill and get paid by your company.

The S2P process generally has four components:

- Source-to-contract

- Procure-to-invoice

- Invoice-to-pay

- Active Supplier Management

These components are key to the operational and business success of all E&Ps. The outcomes include getting goods and services delivered on time and on budget, ensuring work is done in an efficient, effective, and safe manner, and protecting the company from a risk perspective.

Technologies are now available that will allow for the automation of the most routine portions of the S2P process. If the process is automated, a report from McKinsey indicates that 3.5% of total spend can be saved through compliance, reduction of transaction costs, efficiencies, and controls.

The Next Level of Efficiency

The last component of the S2P process is the active management of suppliers, and it is key to the next level of efficiency. The business model of an E&P is to subcontract out most work to suppliers. It follows that the management of these suppliers would be one of the most crucial, with outsized impact to the bottom line.

From a Supply Chain perspective, active management of suppliers means setting KPIs within contracts and ensuring their compliance. This can take the form of cutting-edge approaches like “smart contracts” using blockchain, but we think that the lowest hanging fruit is usually just in good communication.

- From an Operator’s perspective, active management of suppliers is the physical execution of the service which they are hired to do. It’s the right work done by the right people at the right time, safely and responsibly.

- From an Oilfield Service (OFS) company’s perspective, active management of suppliers means transparency and cooperation with an E&P. Clear expectations, collaborative problem solving, and an honest buck.

When all these teams are integrated in their respective functions, both the E&Ps and OFS companies will see the benefit in their bottom line. Work gets done faster and more safely, with higher quality and less waste.

E&Ps and OFS companies that have implemented software for active supplier management have reported reductions in costs, environmental impacts, variances, and safety impacts. In cost reductions alone, expenses have been reduced up to 10% per service category.

Transforming Supply Chain to Unlock Value

Just like software and digital technologies are unlocking additional value in operational teams, the Supply Chain needs to be digitized and automated to realize the full value of what it can bring.

So, let’s talk about how the Supply Chain can be transformed through data and software into a strategic function that can help unlock new value.

Over the next couple of blogs in this series, we’ll detail where the Supply Chain group fits in relation to the Big Six software packages that we’ve discussed before. While the Big Six are crucial, other software is almost always needed to augment a well-functioning Supply Chain group. We’ll also discuss where to invest your dollars in Supply Chain software to get the biggest bang for your buck – and spoiler alert – this could be a game changer for your organization.